How is chocolate made and what is it made of?

Discover how your favorite sweet treat comes to life in this deep dive into chocolate making. Once you learn about the incredible skill, countless steps, and hours of work it takes to transform a simple cacao bean into that chocolate bar you're holding, every single bite will taste even sweeter and more precious.

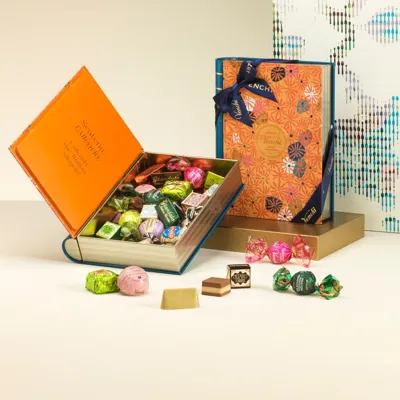

Venchi Best Selling Chocolate

What is chocolate, exactly?

Chocolate, in some form, has been capturing the world’s taste buds for more than 5,000 years, and it’s produced from the seeds of the cocoa tree (Theobroma cacao), which are often called cocoa beans.

Yet there are many steps involved before cacao beans can become the chocolate on our shop shelves. The production process involves fermentation, drying, roasting, grinding, conching, and tempering, all of which require numerous hours and expertise to bring out maximum flavour.

How chocolate is made step-by-step

Learn how a cocoa tree develops into exquisite artisan chocolate, with the step-by-step production process below.

1. Cacao cultivation

The story of chocolate starts with the cocoa tree (Theobroma cacao), which flourishes in hot and humid environments. It’s native to South America, but is now grown all over the world, especially in countries near the equator. Chocolate makers are particularly interested in the fruit of the cacao tree, which contains about 30-50 seeds, famously known as cacao beans, which are the key ingredients in chocolate. A cacao tree often needs to be around 5 years old to be mature enough to bear fruit, but the wait is worth it.

2. Harvesting and Fermentation

Cacao pods are ready to harvest when they’re a bright orange/yellow colour. To make sure that the trees are not damaged and can produce fruit for years to come, most cacao pods are usually chopped off the tree by hand.

The pods are then opened, and the precious cacao seeds, which are about the size of an olive, are taken out. Approximately 2.2 lbs of cacao beans are needed to produce about 1 lb of dark chocolate.

The fermentation stage is when the cacao beans begin to develop some of those iconic chocolate flavours. The beans are usually placed in wooden boxes, covered in banana leaves, and left to ferment for about 2-9 days.

3. Drying

During fermentation, the cacao beans absorb plenty of moisture, which must be dried out. Cacao farmers lay out the cacao beans on wooden mats and leave them to dry out in the hot sun for at least 7-14 days.

The beans will be raked and turned over to make sure that they’re all evenly dried. As you can see, many steps of the process are done carefully by hand using traditional methods.

4. Roasting

Chocolatiers take the roasting stage very seriously. First, they check the beans for quality and remove any debris or mouldy beans, and only then are the beans placed in ovens, and the roasting can begin.

Unlike coffee, cacao beans prefer a slower roast at lower temperatures to help coax out their nutty, chocolate flavours. Roasting times and temperatures can vary and depend on the variety of the beans and their size. Most beans will be roasted at temperatures of 230°F to 302°F for as little as 2 minutes to as long as 2 hours.

5. Cooling and Separating

After roasting, the beans are left to cool down and prepared for the winnowing stage, which separates the outer shell of the beans from the inner cacao nibs and ensures the quality of the final chocolate.

Many producers use a winnowing machine, which first breaks the shells of the roasted beans, and then they use air to blow away the lighter shells and leave behind the heavier cacao nibs.

6. Grinding (making the "cocoa liquor")

Next, the solid cacao nibs (which are made of cocoa solids and cocoa butter) are placed in an industrial mortar and pestle-like machine and ground into a thick paste often called “cocoa liquor”, which, as a fun fact, doesn’t contain any alcohol.

The grinding process can continue for several days, with each passing day creating a smoother texture that helps the chocolate feel creamy once in the mouth. It’s during the grinding stage that ingredients such as sugar and milk powder are mixed in.

7. Conching

Every gourmet chocolate goes through the conching process, which involves kneading, heating, and aerating the chocolate paste for maximum aroma, taste, and silkiness. This is an essential step that makes sure the chocolate is consistent in texture and flavour.

8. Tempering

As most at-home bakers will know, tempering chocolate is a process of gently heating and cooling the chocolate to bring it to its most stable form. Well-tempered chocolate has an irresistibly glossy look and “snaps” when bitten into.

9. Moulding and packaging

After the chocolate has been tempered, it’s poured into moulds and left to cool on its own or placed in cooling tunnels until it becomes solid. To eliminate any air bubbles, the moulds are tapped against a hard surface.

Finally, it’s wrapped in foil or paper packaging and begins its journey to all the chocolate lovers, ready to be enjoyed.